In case you have watched any of the old Sherlock Holmes movies, steam trains and bullock carts are used as the primary way for transportation; you also may have noticed the post-offices using an empty cylinder to transport letters. These are called 'pneumatic tube systems.'

While they were popular back in the 19th century, now they are not being used in post offices and stock exchanges. But that is about to change as over the years the system has become much better and efficient. Before we show you how pneumatic tube systems (PTS) will change the future, let's see the current scenario.

Applications of PTS and the current scenario

Currently, you won't see many tubes inside any offices or residential buildings. Still, the pneumatic tube system is mainly used today in transporting small objects in a close and convenient location. This provides speed and efficiency without wasting any time.

More prominent use of pneumatic tubes can be seen in nuclear plants. In atomic plants the radioactive isotopes have a brief life span; therefore, speed is essential. Here samples must be moved from the nuclear reactor core to the instrument where the resulting radiation records are being registered. Here are some more day-to-day uses of the pneumatic tube system.

In Retail stores

Many big retailers such as Walmart, Home Depot, and IKEA across the globe use pneumatic tubes to transport cash and product safely and efficiently. Pneumatic tubes can save operational costs by improving the operational efficiency of moving cash and also enhance security by reducing the reliance on manpower.

According to a recent survey, it is found that retail fraud in the US increased by 7.3 % in 2020. This means that every $1 and by the US retailers cost them $3.36. The number of retail frauds is growing day-by-day, hence it is more important than ever to secure your system using safe transfer methods like a pneumatic tube system.

In production

Pneumatic tube systems are a reliable and efficient alternative for transporting materials between industrial plants. High-speed pneumatic tube systems are easy to integrate with the current manufacturing plant, and therefore by maximizing operational facilities, they provide a quick return on your investment.

The pneumatic tube system allows manufacturers to transport spare parts, documents, and small materials, safely and swiftly across different departments in a manufacturing plant. The pneumatic tubes accelerate the production rate and reduce the travel time it takes to transport materials from one department to another.

In hospitals

Hospitals and other places where every second counts and speed in transportation is essential are the best places for PTS implementation. For example, during an open-heart surgery where blood is required urgently, then speed is vital; therefore, with a pneumatic tube system, the transport of items like blood bags can be safe and efficient.

In terms of profits and cost efficiency, pneumatic tube systems are the best option. A transportation system like this increases operating efficiency. This way, the hospital employees can have more free time on their hands and concentrate more on patient health care and other critical work.

How much does it cost?

To estimate the cost of a PTS many variables have to be calculated based on the customer requirements and preferences. The number of parameters that have to be taken into consideration will make your head spin.

This all requires a great order of planning, from installing a handful of stations in the building and setting up a tubing network that connects all stations. Therefore, the cost varies. For calculation, it is also necessary to know whether the tube system is to be integrated with an existing building or to be included during the building's construction. There is no definitive answer of how much it costs to implement a pneumatic delivery system.

Find a PTS manufacturing company and contact them as they will understand customers' requirements. Base on the given specifications, the firm will estimate the cost of a PTS.

Benefits of implementing a PTS

- Increase in the speed of delivery tasks at a much greater extent

- The workforce efficiency can be greatly improved.

- While delivering sensitive specimens in hospitals, damage to them can be prevented.

- Low maintenance is required as there are fewer moving parts involved.

- A lot of operational costs can be saved in terms of workforce and maintenance.

- Due to the improvement in PTS over the past few years, now it can be customized as per requirements.

ROI on the implementation of PTS

Before implementing PTS, the user must investigate the following parameters.

- Contents the PTS is going to potentially transport.

- Working practices and evaluate how the system will be utilized.

- Design the tubing network to handle the required amount of traffic.

Then the user needs to focus on weighing the costs against benefits. Here are some points that must be taken into consideration.

- PTS can save a drastic amount of time, manpower, and elevator usage.

- Samples in hospitals can be transferred safely and securely.

- As pneumatic tubes work on just air pressure, there is little need for maintenance.

- In a new building, it allows users to place the system where it is needed most, unlike old buildings where there are certain limitations.

Future of the PTS

Here is how we may see applications of PTS in the near future,

Future implementation of pneumatic tubes

Future implementation of pneumatic tubes

In transportation

Expected design of Hyperloop

Source : Adobe Stock royalty free images

Expected design of Hyperloop

Source : Adobe Stock royalty free images

Looking at the future, Tesla CEO Elon Musk proposed a big-scale version of a pneumatic tube system to transport people between cities at a speed of about 700 miles per hour.

This concept was later named Hyperloop, and it certainly has captured a lot of attention from people by regularly appearing in the news. The work is still in progress and we might see it by 2040. It is essentially the same as a pneumatic tube system in which the passenger cars are pushed or pulled by the difference in air pressure. Companies like Virgin and Vactrain are also working on developing a similar transport system.

While the pneumatic tube concept is a lot old and many previous attempts have been made to make this a mode of transport, none succeeded, and steam engines prove to be cheaper, more flexible, and reliable. But the idea was reborn in the 20th century, and we have also seen a handful of successful small-scale implementations of Hyperloop around the world.

In waste disposal

Even in waste disposal, an underground pneumatic tube system with high-pressure air can be a great way to dispose of garbage away from the living areas to a centralized collection point.

In cities like Stockholm, households use this garbage collection system in their apartment buildings. Garbage like food waste and plastic goes into separate cylinders then travel through the pneumatic tubes and wind up in an incinerator. Powerful fans pull the garbage through the pipes at speeds of up to 60 miles per hour, and it reaches collection facilities within a few seconds.

Countries like Norway have found this garbage disposal method efficient and are now trying to implement them in their own country by installing underground pipes. The government will later maintain them.

Growth of PTS

Growing demand of PTS in major countries

Source : Markets and Markets

Growing demand of PTS in major countries

Source : Markets and Markets

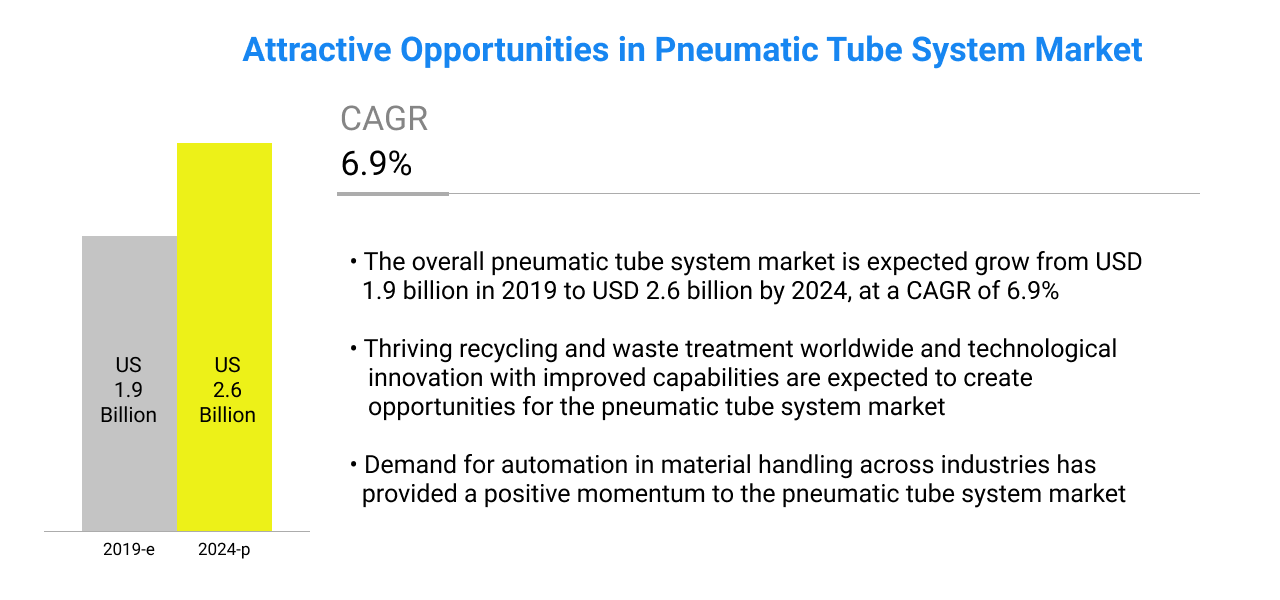

The pneumatic tube system marketplace is expected to grow from $1.9 billion in 2019 to $2.6 billion by 2024. This is a growth rate of 6.9 %. Many factors drive such high demand for pneumatic tube systems, and they are spread across different industries like medicine, emerging e-commerce industry, and supply chain industries. As per a report around $2.4 million worth of units have been imported by India between 2015-16 only.

Another factor for the increasing demands is that governments in many countries emphasize safety and security on production floss, which can be achieved best by installing pneumatic tube systems for transporting materials. In countries such as India, Japan, and China, the pneumatic tubes market is witnessing rapid growth and therefore is seeing increasing investment activities by many of the developed countries as well.